How Thermal Transfer Printing Maintains Color & Clarity Over Time

How Thermal Transfer Printing Maintains Color & Clarity Over Time

Thermal transfer printing is a trusted method for producing durable, high-resolution labels, tags, and decals — especially where longevity and legibility matter. Unlike direct thermal printing, which relies on heat-sensitive paper, thermal transfer uses a ribbon that transfers ink (wax, wax-resin, or resin) onto the substrate, producing prints that resist abrasion, chemicals, heat, and UV. Here’s a practical guide to why thermal transfer prints remain readable and attractive long after they leave the press — and what you should specify to maximise lifespan.

🔧 The Core Reasons Thermal Transfer Prints Last

- Ink Fusion: Resin and wax-resin ribbons partially fuse with the substrate surface, creating a bonded layer that resists rubbing and smudging.

- Choice of Ribbon: Wax (economical), wax-resin (balanced durability), and resin (highest chemical & heat resistance) let you match longevity to the use-case.

- Substrate Compatibility: Coated papers, synthetic films (PET, polypropylene, polyimide), and specially treated materials accept inks differently — choosing the right substrate ensures optimal adhesion and clarity.

- High Print Density: Proper print head settings yield crisp edges and solid fills, reducing the risk of fading or patchy prints.

🧪 Material & Ribbon Selection — Match Use Case to Durability

- Wax Ribbons: Best for general-purpose labels (shipping, retail). Good clarity for text/graphics but limited chemical/heat resistance.

- Wax-Resin Ribbons: A versatile middle ground — improved scratch and smudge resistance while still cost-effective for many product & logistics labels.

- Resin Ribbons: Premium durability — ideal for harsh environments (industrial, chemicals, high heat). Offers the strongest resistance to solvents, abrasion, and UV exposure.

- Substrates: Synthetics (PET, PP, BOPP) outperform paper in longevity and moisture/UV resistance. For outdoor or long-term indoor use, pick a synthetic substrate designed for your environment.

🌞 Environment & Exposure: Plan for Conditions

- Heat & Sunlight: High temperatures and UV accelerate fading. Use resin ribbons + UV-stable substrates for outdoor or Gulf-climate applications.

- Moisture & Humidity: Synthetics paired with wax-resin or resin ribbons avoid bleeding and adhesion loss in humid conditions.

- Chemical Exposure: For contact with oils, solvents, or cleaning agents, resin ribbons and chemically resistant films are essential.

🖨️ Printer Settings & Maintenance Matter

- Print Head Temperature: Correct heat ensures proper ink transfer — too low causes faint prints; too high can over-melt ribbon and blur details.

- Print Speed vs Quality: Slower speeds typically improve sharpness. Balance speed with required resolution for barcodes and small text.

- Head Pressure & Alignment: Uniform pressure avoids banding and uneven prints; regular calibration keeps results consistent.

- Routine Cleaning: Clean print heads, platen rollers, and ribbon paths to prevent residue build-up that degrades image quality.

🛡️ Protective Finishes & Post-Print Protection

- Lamination & Overlaminates: Clear films or liquid coatings further protect labels from abrasion, UV, and chemicals when required.

- Topcoats: UV-cured varnishes or matte/gloss topcoats add an extra protective barrier for sensitive applications.

📐 Design & Artwork Tips for Long-Term Legibility

- Barcode & Small Text: Use proper barcode sizes, quiet zones, and verification tools (scanners/verifiers) to ensure readability over time.

- High Contrast: Dark-on-light or light-on-dark colour combinations improve scanning and viewing from a distance.

- Avoid Fine Hairlines: Very thin strokes or tiny serifs can fill in or wear off; prefer slightly heavier strokes for enduring clarity.

🧾 Quality Control & Testing

- Environmental Testing: Simulate heat, humidity, abrasion, and chemical exposure to confirm ribbon+substrate performance.

- Barcode Verification: Use ISO/ANSI barcode verifiers to ensure scannability immediately after printing and after stress tests.

- Sample Runs: Approve physical samples before large production runs — especially for branding-critical or safety labels.

💼 Typical Applications & Recommended Configurations

- Retail & POS Labels: Wax-resin ribbons on coated paper or PP for shelf life & gentle handling.

- Warehouse & Logistic Labels: Wax or wax-resin on durable PP for clear barcodes and moderate handling.

- Industrial & Chemical Tags: Resin ribbons on polyester or polyimide for extreme chemical and heat resistance.

- Outdoor Signage & Asset Tags: Resin ribbons + UV-stable synthetic films + optional lamination for long-term exposure.

✅ Best Practices Checklist

- Choose ribbon & substrate based on environment (heat, UV, chemicals).

- Set the printer to correct temperature and speed for your ribbon type.

- Use vector logos and high-contrast artwork; avoid tiny fine lines for critical info.

- Keep printers clean and calibrated; schedule routine maintenance.

- Test and verify barcodes and adhesion before full-scale production.

- Consider lamination/topcoats for extra abrasion and UV protection.

📞 Partnering with Experts

Thermal transfer printing delivers exceptional longevity when components are matched correctly and the production process is managed well. At Al Mariya Design Spot, we help businesses in Abu Dhabi and the UAE choose the right ribbons, substrates, printer settings, and finishing options — so your labels, tags, and stickers stay clear, scannable, and brand-perfect for their intended lifespan.

Contact us for material samples, stress-testing, or a tailored labeling plan for your products and operations.

#ThermalTransfer #LabelPrinting #DurableLabels #BarcodePrinting #AlMariyaDesignSpot #AbuDhabiPrinting #IndustrialLabels

Vehicle Graphics

Vehicle Graphics Branding

Branding Stickers

Stickers Hoarding

Hoarding Exhibition Stands

Exhibition Stands UV Flatbed Printing

UV Flatbed Printing Signage

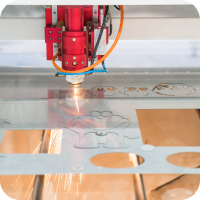

Signage Laser Cutting

Laser Cutting Screen Printing

Screen Printing Digital Fabric Printing

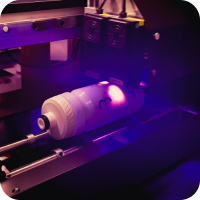

Digital Fabric Printing Thermal Transfer

Thermal Transfer Personalized Gifts

Personalized Gifts Promotional Products

Promotional Products Flag Printing

Flag Printing Website & Digital Marketing

Website & Digital Marketing